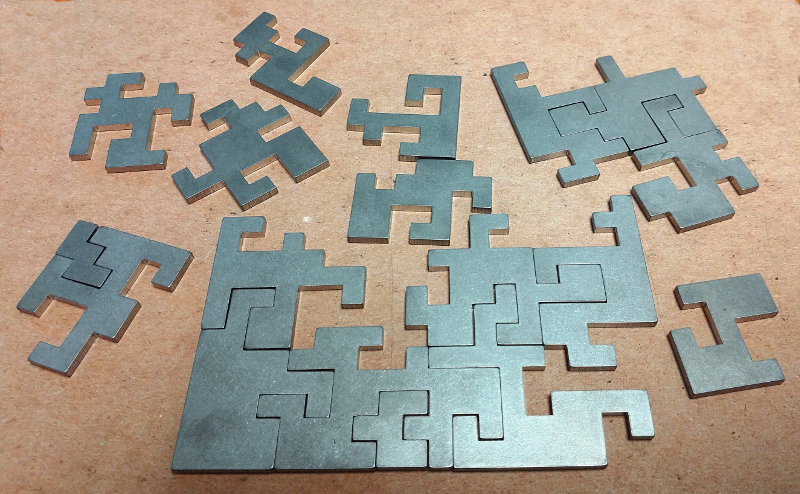

Laser Cut Puzzles

I love metal and jigsaw puzzles can be entertaining so why not make one out of metal? I don't remember why I thought of it but once the question is asked the answer is obviously: yes I should make one. As an engineer by day I have a fair knowledge of commercial manufacturing in addition to do it yourself solutions so I decided almost immediately that I wouldn't mess around with cutting something out by hand or anything like that.

There are a variety of processes that could be applicable for something made out of sheet/plate. Some of the more common ones are: oxy-fuel cutting, plasma cutting, stamping, laser cutting, photochemical etching, milling, and waterjet cutting.

I knew that I wanted something in what I would consider the desk toy size range. Maybe about the size of a mousepad and thick enough that it would show off the fact that it was made of metal and had some heft. That narrows down the choices considerably so I didn't even consider some: Oxy-fuel is generally used for larger parts, photochemical is used for smaller thin things, stamping is for thinner things and higher production volumes, milling is usually more expensive than other options.

That leaves plasma, laser and waterjet cutting. Plasma is the most available and cheapest of these where applicable but has looser tolerances and larger kerf widths (cutting lines) than the other two. It can also have problems with part distortion when there is a lot of heat put into the material by cutting a bunch of small details close together. In this case I didn't think it would be good enough to make a nice puzzle.

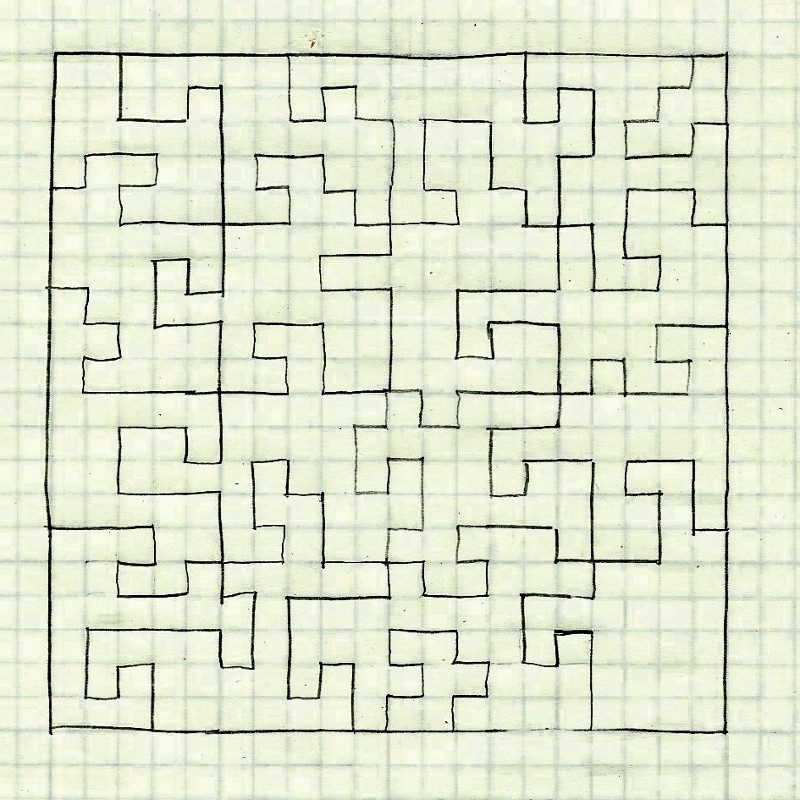

I say not good enough to make a nice puzzle but I haven't really explained exactly what was in my mind at this point. I had settled on something roughly 1/8" to 1/4" thick with interlocking pieces laid out on a square grid. Something like this sketch on my ever present engineering graph paper.

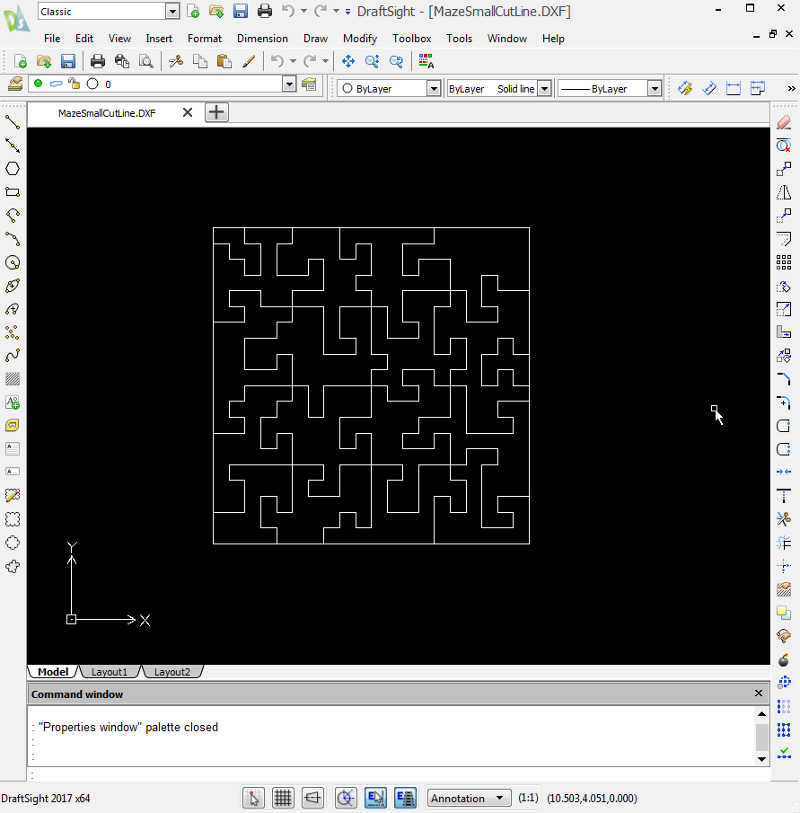

I find sketches good for exploring ideas quickly and if you talk to a shop that does laser/water/oxy-fuel/plasma cutting they can often make a part based off of that if you give them enough information on size and tolerance. You will pay for their drafting time though and many places won't bother quoting you unless you already have a relationship with them so it is really a good idea to make a complete drawing nd when applicable give them a CAD file. In this case nothing fancy, just a simple 2D 1:1 scale DXF with lines everywhere I want cut.

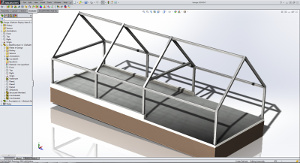

I happened to use Solidworks to make my DXF since that is what I use every day but there are a large number of 2D CAD programs one can use. Dassault Systems (Solidworks) even makes a pretty decent one called Draftsight which you can download for free.

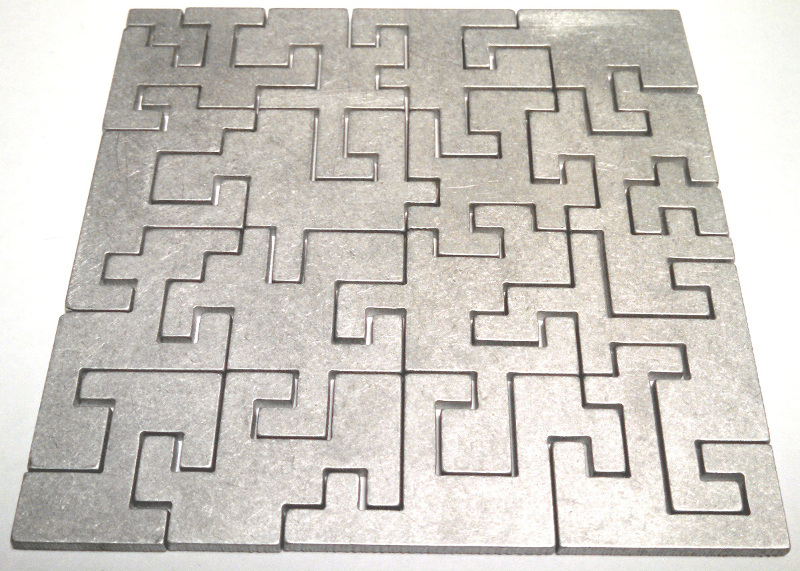

Anyway, I had a DXF and was ready to get a quote on making a few of these. We have one laser shop in Bryan/College Station and I know that their system is really not set up for things as small as this so I started talking to a local shop (2nd Generation Arc 'N' Spark) with a waterjet. They said that with 1/8" aluminum they could use a .020" orifice (I wanted as thin of a kerf as possible) and make a batch of 5 for $173. A little on the high side for Christmas stocking stuffers but I really wanted to make them so I said do it.

They made them pretty quick and like I thought they were pretty cool. Cool enough that I started thinking about a bigger batch and making them cheap enough that I could sell a few. I did want to change a few things though. The .020" kerf from the waterjet worked but was a little looser than I liked. They were also a little on the light side since they were made out of aluminum (I chose aluminum at first because waterjet cuts it quicker/cheaper than stainless steel).

A smaller kerf, lower cost target and switch to stainless really pointed toward trying out a laser shop if I wanted to go forward with making another batch. As I mentioned before the shop in town that has one wasn't set up for the kind of parts I was talking about but I knew that somewhere someone was so I started looking up shops and getting quotes. The best quote and a vendor that I have used a few times since was Ambox Ltd in Houston. They apparently have fiber lasers that are really set up for this kind of stuff.

This machine isn't theirs (picture by Metaveld BV [CC BY-SA 3.0 or GFDL], via Wikimedia Commons) but shows what an industrial metal cutting laser machine looks like for reference. This isn't the kind of thing that someone is talking about if you hear that a local hackerspace or your neighbor has one. Those are a completely different class of tool with at most 1/10th of the power needed to cut metals in any serious way.

Anyway, full sheets is really kind of a major breaking point in cost for a place like this so I got a quote for a full sheet and also a smaller trial run. The nice thing about their quote was they discounted the trial cost from the full sheet price if I decided to go through with the full run. At this point I wanted to at least see how the laser cut stainless ones would be so I ordered the trial set.

They were even better than the aluminum ones for sure. 3x as heavy and definitely tighter fitting with a .012" kerf instead of .020". But was I really going to order a whole sheet of them? I thought about it and decided I'd go ahead. Worst case I'd have 200lbs of puzzles hanging around for the rest of my life reminding me not to do something like that again.

Before I placed the order I thought of something though. I would forfeit rolling the cost of the prototypes into a full sheet batch but I should make the big batch a different pattern so I could show people pictures of the puzzle without showing the solution. So I drew up a new pattern and then had a big batch made.

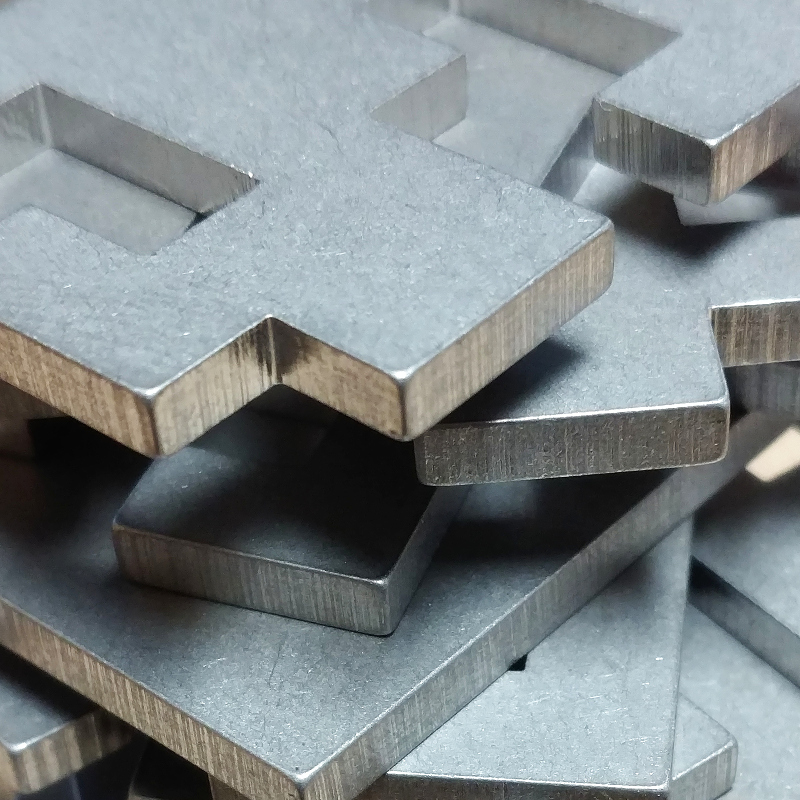

One thing that I haven't mentioned yet which gets to be kind of important when contemplating a lot of these is the sharp edges that waterjet and laser cutting leaves (particularly the laser). You can see in the next picture that the cut edges are sharp and there are some particularly poky bits where a tiny tab was left to help hold everything together in the machine. You can also see some things I think are cool. Notably the discolored HAZ (Heat Affected Zone) next to the cut and then fine ridges in the shiny cut surface.

Obviously those sharp edges have to be dealt with but I'm certainly not going to sit around and file or sand them all off. The answer is some kind of tumbling or vibratory deburring. I don't have a big machine for that and keeping each individual set of puzzle pieces together instead of trusting all the parts to be interchangeable is probably the smart move. My solution for now at least is cheap and simple. A tiny rock tumbler with some cheap abrasive media.

This solution actually took awhile to figure out completely. Sand didn't work at all, the full size triangles by themselves didn't get into all the corners well enough, doing it dry made things not mix well and took longer, soap in the water just made a mess, etc... I finally ended up with a mix of abrasive sizes (break some of the larger triangles into smaller pieces and then keep adding a couple of large triangle every now and then so there is always a mix of larger, medium and small abrasive particles circulating) and a drum 3/4 full of plain water.

Now that I got it all worked out I throw a puzzle in there and leave it for a day, then take it out and repeat as needed. It is going to take awhile but the result is pretty good. Just the right amount of corner rounding and an attractive random matte finish which hides scratches.

That's it. If you feel like grabbing a puzzle for yourself I'll eventually make a store and put some on it: Laser Cut Puzzles. I have a feeling there will be a large stack of these in a corner of my house for many, many years to come.